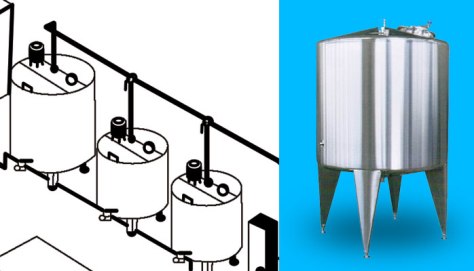

After homogenize, the next step of ice cream processing is age the mix. The mix is aged in the Ice Cream Aging Vat. Ice cream mix is aged at 40°F (5°C) for at least 4 hours or overnight. Aging the mix cools it down before freezing, allows the milk fat to partially crystallize and the gives the proteins stabilizers time to hydrate. This improves the whipping properties of the mix.

Some changes have happened during ageing. First, the emulsifiers (lecithin from the egg yolks) absorb to the surface of the fat droplets, creating a weaker membrane that is more susceptible to partial coalescence. When the mix is frozen in the ice cream machine, it undergoes partial coalescence, during which clumps of the fat globules form and build an internal fat network. These fat globule clumps are responsible for stabilsing the air cells and creating a semi-continuous network of fat throughout the product resulting in a smooth texture and resistance to meltdown. Second, cooling the mix to below 4°C causes the fat inside the droplets to begin to crystallise. Nearly complete crystallisation is needed to promote coalescence of fat globules when the mix is frozen in an ice cream machine. Cooling a mix to 0-2°C increase the rate of crystallisation. If you do not sufficiently age your mix, your ice cream can suffer from defects similar to those found in mixes with no added emulsifiers: less retention of shape and relatively fast meltdown. It will also be difficult to stabilise air bubbles during the whipping stage, resulting in a hard chewy texture.